We Offer a Variety of Weight Indicators to Meet Your Needs

Anchor Type Weight Indicators

Anchor Type

Dicks Oilfield Instrument Sales & Service Inc. anchor type weight indicators are made to be accurate and durable. Our systems are compatible with all major deadline anchors. Our anchor type weight indicator systems operate using a compression or tension load cell to display accurate, reliable measurements. When the load cell is compressed, hydraulic fluid is forced through the load cell to the weight indicator by way of a high-pressure hydraulic hose. Once the pressure reaches the indicator, the outer dial measures weight on bit, and the inner dial measures total hook load. Each gauge is designed with 2 pointers for more accurate readings, and the Vernier pointer offers 4:1 sensitivity and greater accuracy.

MODEL 150 (AT 111)

Supports loads up to 150,000 lbs.

10, 12, 14, and 16 Lines Strung

50 Sq. In. Anchor Type Compression Load Cell

16" Indicator

MODEL 125 (AT 110)

Supports loads up to 125,000 lbs.

10, 12, 14, and 16 Lines Strung

50 Sq. In. Anchor Type Compression Load Cell

16" Indicator

MODEL 100 (AT 104)

Supports loads up to 100,000 lbs.

8, 10, 12, and 14 Lines Strung

50 Sq. In. Anchor Type Compression Load Cell or 36.767 Sq. In. Bronze Tension Load Cell

16" Indicator

MODEL 75 (AT 1113)

Supports loads up to 75,000 lbs.

6, 8, 10, and 12 Lines Strung

50 Sq. In. Anchor Type Compression Load Cell or 36.767 Sq. In. Bronze Tension Load Cell

16" Indicator

MODEL 50 (AT 102)

Supports loads up to 50,000 lbs.

6, 8, 10, and 12 Lines Strung

36.767 Sq. In. Anchor Type Compression Load Cell or 36.767 Sq. In. Bronze Tension Load Cell

16" Indicator

MODEL 40 (AT 101)

Supports loads up to 40,000 lbs.

4, 6, 8, and 10 Lines Strung

16.1 Sq. In. Anchor Type Compression Load Cell or 16.1 Sq. In. FS Tension Load Cell

12" Indicator

MODEL 30 (AT 108)

Supports loads up to 30,000 lbs.

4, 6, and 8 Lines Strung

16.1 Sq. In. Anchor Type Compression Load Cell

12" Indicator with Target Pointer

How To Order

- Specify Panel Or Box Mount

- Specify Single Line Load

- Specify Anchor Used

- Specify Wireline Size

- Specify Gauge Size (12" Or 16")

Instrumentation's Anchor

Specifications:

Panel mount and box mount versions are available, in either English or Metric divisions. Each system consists of a diaphragm type load cell, high pressure hose assembly with disconnects, 12" or 16" indicator with complete dial set and damper assembly and recharge kit consisting of hand pump, and (1) qt. of instrument fluid. Heavy duty steel box or console for mounting of additional gauges is also available (optional).

Features:

- Models available for deadline loads from 30,000 pounds to 200,000 pounds.

- Indicator includes outer dial (vernier) for direct weight-on-bit reading and inner dial for total hook load.

- Hook load and vernier dampers are designed to dampen excessive pointer movement and extreme shock during tough drilling situations.

- Includes vernier bit weight indicator with 4:1 sensitivity for highest accuracy possible.

- High pressure, rugged hose and disconnect sets are included with each system.

- Large, easy to read indicators available in 12" or 16" versions.

- Panel mount or box mount versions available with optional heavy-duty steel box or console for custom configuration of your choice of hydraulic instruments and meter combinations.

- Compatible with all industry-standard deadline anchors.

Drilling Rig Instrumentation

ANCHORS FOR E, ED, 125 & 150 WEIGHT INDICATOR SYSTEMS

The National Type EB

The National Type EB, for Type E or Type EB Weight Indicators, with E80 Tension Load Sensor.

Mounts on floor or substructure. Type E System designed for 1-1/4", 1-3/8", and 1-1/2" wireline

sizes. Type EB Systems designed for 1-1/2" and 1-5/8" wireline sizes.

Drum diameter 28".

Net weight 1560 Ib.***

The Hercules Model HA 131T

The Hercules Model HA 131T, for Type E or Type EB Weight Indicators, with E80 Tension Load

Sensor. Mounts on floor or substructure. Type E System designed for 1-1/4", 1-3/8", and 1-1/2"

wirelines. Type EB Systems designed for 1-1/2" and 1-5/8" wirelines.

Drum diameter 28".

Net weight 1460 Ib.**

The Hercules Model HA 120T

The Hercules Model HA 120T, for Type E or EB Weight Indicators, with E551 Compression Load

Sensor. Designed for 1-1/4", 1-3/8", 1-1/2" and 1-5/8" wirelines.

Drum diameter 28".

Net weight 1475 Ib.***

The Hercules Model HA 130T

The Hercules Model HA 130T, for Type 125 Weight Indicator, with E551 Compression Load Sensor. Designed for 1-1/2", 1-5/8" and 1-3/4" wirelines.

Drum diameter 31".

Net weight 2200 Ib.***

The Hercules Model HA 150T

The Hercules Model HA 150T, for Type 150 Weight Indicator with E551 Compression Load

Sensor. Designed for 1-5/8", 1-3/4", 1-7/8" and 2" wireline sizes.

Drum diameter 36".

Net weight 3050 Ib.***

***Wireline size must be specified when ordering.

• Systems available in pound, kilogram, and decanewton models.

• System consists of weight indicator and wireline anchor with load sensor

ANCHORS FOR D WEIGHT INDICATOR SYSTEMS

The National Type D

The National Type D, for Type D Weight Indicator, with E80 Tension Load Sensor. Mounts on floor or substructure. Designed for 1", 1-1/8" and 1-1/4" wireline sizes.

Drum diameter 24".

Net weight 1080 Ib.**

The Hercules Model HA 129T

The Hercules Model HA 129T, for Type D Weight Indicator, with E80 Tension Load Sensor.

Mounts on floor or substructure. Designed for 1", 1-1/8" and 1-1/4" wirelines.

Drum diameter 24".

Net weight 810 Ib.***

The Hercules Model HA 119T

The Hercules Model HA 119T, for Type D Weight Indicator, with E543 Compression Load

Sensor. Mounts on floor or substructure. Designed for 1", 1-1/8" and 1-1/4" wireline sizes.

Drum diameter 24".

Net weight 820 Ib.**

Deflection Type Weight Indicators

DEFLECTION TYPE (DT101)

- Dicks Oilfield Instruments' Deflection type weight indicator is ideal for use with small to medium drilling and workover rigs.

- Unit is portable, rugged, and dependable. Ready to be placed on the drill line right out of the box.

- Deflection type load cell may be used on wire line sizes 7/8" - 1 1/4"

- The system comes with a self-contained steel box. Weight indicator head is complete with 10 dial set for use with different wire line sizes and lines strung, 25 ft hose assembly, and deflection type load cell with c-clamp.

- Available in English and Metric divisions.

HOW TO ORDER

- Specify Single Line Load Capacity

- Specify Size And Number Of Lines

- Specify Scale Needed (LBS, KGS, DANS)

Mini Weight Indicator (W8D100)

- For use with small drilling and production rigs up to 3,000 lb single line load.

- System comes with 6' or 8.5' gauge mounted in rugged metal box 25 ft hose assembly with disconnects, and either piston or diaphragm type load cell.

- Available in English and Metric divisions.

- Dual dial faces available. Common reeving patterns of 2/4, 4/6, 6/8.

- Load cell attaches to rig floor with a universal clevis or shackles, which eliminates the use of an anchor.

HOW TO ORDER:

- Specify Rig Size And Number Of Lines Strung

- Specify Scale Needed

- Specify Hose Length (25 Ft Standard)

- Specify Type Of Load Cell Required

Wireline Indicators

Features:

- Available in standard capacities of 2000, 3000, 4000, 5000, and 10,000 pounds and the Metric equivalent. Other capacities available upon request.

- Wireline conversion units for 3-sheave devices available for truck mounted wireline applications. These systems come with 10:1 ratio dual pointer gauge and aluminum compression type load cells.

- Systems are provided fully assembled, ready to use right out of the box, calibrated to within percent accuracy.

- Heavy-duty hydraulic hose available in lengths up to 100 feet.

- Easy to read, 6" dial face available in pounds, kilograms, decanewtons or dual scale.

- Integral damper assembly increases pointer sensitivity for accuracy even with the smallest loads.

- Rugged, durable design

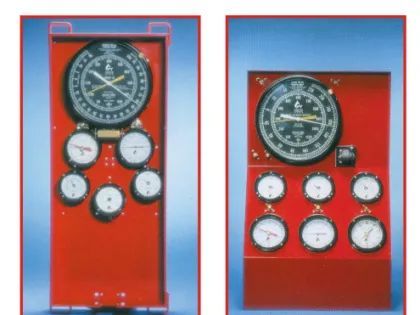

Hydro-Mast Weight Indicators

FAST, EASY LOAD CONTROL FOR SERVICE UNITS.

The easiest/most versatile way for a well servicing operation to control hook load while running a double-fast-line or swabbing with a sand line, is with a Hydro-Mast Weight Indicator.

This reliable hydraulic system will read weights of up to 360,000 Ib., whether the deadline is fastened to an anchor, traveling block or crown. It's ideal for any well servicing rig.

The system consists of an indicator, one or two-pad compression-type load cells (depending on the type of mast), interconnecting hydraulic hoses with quick-disconnect fittings at the gauge end, plus hydraulic fluid for the instrument and a hand pump. It is completely calibrated, sealed at the factory and comes ready to install and use.

When installed, the Hydro-Mast Weight Indicator will detect the slightest weight change. Such activity will cause the compression load cell to generate a hydraulic pressure signal which travels through the connecting hose to the Bourdon tube of the gauge. Tube movement drives the single and/or dual pointer indicator.

Three Configurations That Measure Up

Type HM-6-1 is a single pad load cell system with a zero-adjust six-inch gauge and adjustable damper. The target pointer can be set for the maximum weight desired. The single load cell senses the total weight of the mast and hook load, and it relays the hydraulic signal to the weight gauge. This system is available in ranges of 0-25,000, 0-50,000, 0-100,000 and 0-150,000 Ib.

Type HM-6-2 is a two-pad load cell system. The indicator has one six-inch gauge with a hook load pointer and adjustable target pointer.

Two smaller gauges provide the weight of each pad to help the operator equally distribute the load. Thus, an integrator provides the signal to the large gauge. Choose from capacities in ranges of 0-50,000, 0-100,000, 0-150,000 and 0-240,000 Ib.

Type HM-8-2, also a two-pad system, features a larger 8½ inch main gauge which utilizes a zero-adjust dial with two pointers. One pointer indicates hook load while the 4:1 ratio vernier provides a magnified indication of the slightest hook load changes. Capacities are available in ranges of 0-120,000, 0-150,000, 0-160,000, 0-240,000, 0-300,000 and 0-360,000 Ib.

Designed For Precision, Built To Last

The Hydro-Mast Weight Indicator provides accurate readings over its long service life. All systems are housed in a heavy-duty steel box with removable front and back doors to protect the gauges during shipment, installation, and removal. A two-inch diameter coupling is welded to the bottom of the cabinet for mounting on a pipe stand for increased visibility.

Additionally, these Dicks gauges are fluid-filled to lubricate, prevent rust, soften vibration, and avoid fogging.

Contact a Dicks Representative for proper application information.

Nobody does it better.

Dicks has been the first name in drilling instrumentation for over 25 years. In fact, no other company has a more enviable record of "firsts" in drilling instrumentation and data systems.

But being first is not enough. Dicks sets the most rigid standards in the industry. Not just for products, but for people as well. That's why Dicks’ service is legendary. Dicks personnel have years of firsthand experience in the oil field. They're on-call 24 hours a day, seven days a week from more Technical Service Centers than any other instrumentation company in the industry. So, rest assured that Dicks provides accurate installation and quality service, no matter where the rig is.

Dicks Oilfield Instruments

Sales & Service

3110 N FM 1936

Odessa, TX 79764

doisales@aol.com

24/7 SERVICE

Phone:

(432) 381-6565

24 Hour Service Toll Free:

Request A Quote

Contact Us

We will get back to you as soon as possible.

Please try again later.